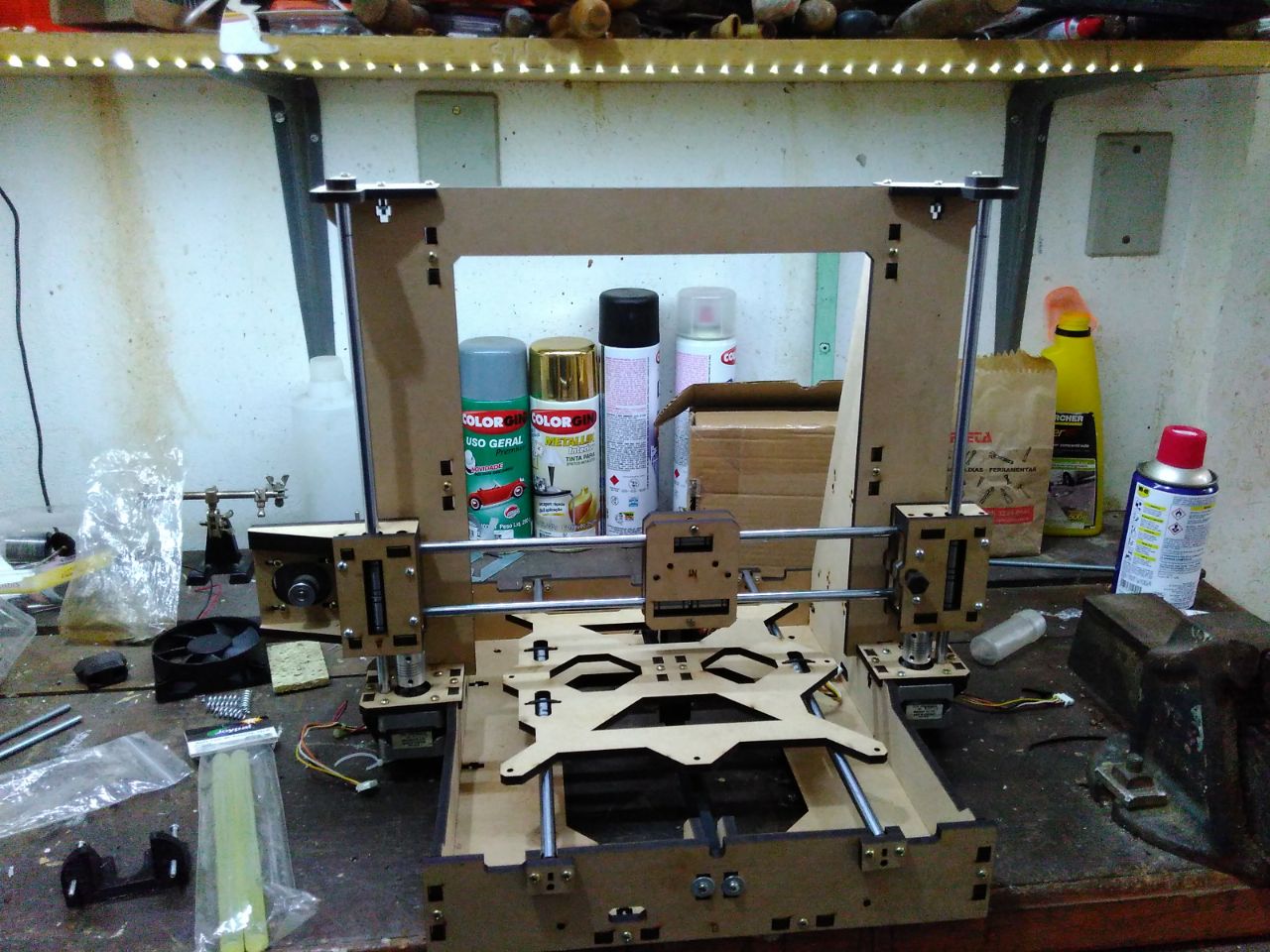

Graber i3 Tutorial - Finished !

2017-01-30[ graber diy 3d printer ]

3D printing, also known as additive manufacturing (AM), refers to various processes used to synthesize a three-dimensional object.[1] In 3D printing, successive layers of material are formed under computer control to create an object.

These objects can be of almost any shape or geometry, and are produced from a 3D model or other electronic data source. A 3D printer is a type of industrial robot.

After this Wikipedia preview we can start work !

- Files for the laser cut - graber_lasercut

- Bill of Materials

- Where and what buy:

- RAMPS (electronic, China) - Big screen - Small screen

- A4988 (electronic, China, some of drivers can screw up) - Here

- Hotend (extruder, China) - Here

- MK8 (extruder, China) - Here

- Cooler (extruder, China) - Here

- HeatBed (extruder, China) - Here

- Gear and Belt (to X and Y axis, China) - Here

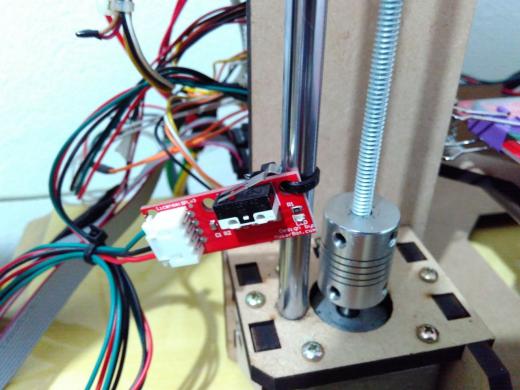

- Endstop (X,Y and Z axis, China. Not tested yet !) - Here

Ok, the total price is:

| What | How much | $ |

| RAMPS | 1 | 28.5 |

| A4988 (optional) | 1 | 5.82 |

| Hotend | 1 | 4.68 |

| Cooler | 2 | 0.88 |

| Mk8 | 1 | 0.82 |

| Heatbed | 1 | 8.1 |

| Gear and Belt | 1 | 5 |

| Endstop | 3 to 6 | 0.37 |

| Total | 54.17 |

- Ok, now in Brazil:

Total price:

| What | How much | R$ |

| MDF 6mm (810 x 460mm) | 1 | 25 |

| Glass | 1 | 10 |

| Smooth roads | 6 | 110 |

| Motors (Nema) | 5 | 190 |

| 12V 20A | 1 | 50 |

| Total | 385 |

The total of everything is R$ 601 (Reais) or $ 151 (Dolar).

Software

We need 3 kinds of software (ITS FREE):

- The Slicer

- Converts the model into a series of thin layers and produces a G-code file containing instructions tailored to a specific type of 3D printer. This G-code file can then be printed with 3D printing client software (which loads the G-code, and uses it to instruct the 3D printer during the 3D printing process).

- The graphical interface - Pronterface - Repetier

- Interface to communicate and use the 3D printer.

- Firmware for RAMPS - All of them (I am using Marlin)

- Software to burn the Arduino Mega.

Where am I ?

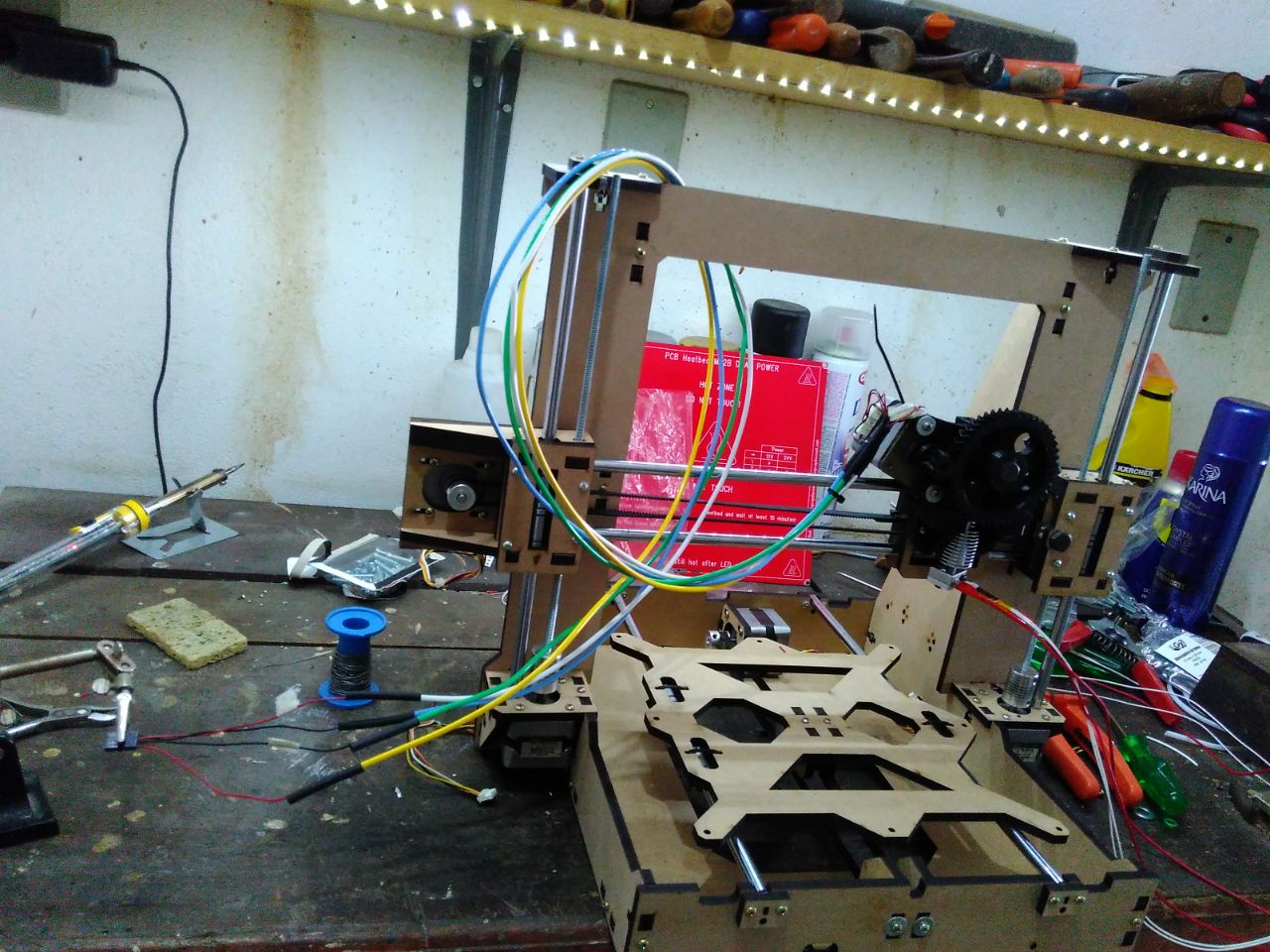

Now I am making some moving testes of the axis, speed and acceleration. Until now everything is ok, just need to finish the extruder and start to print !

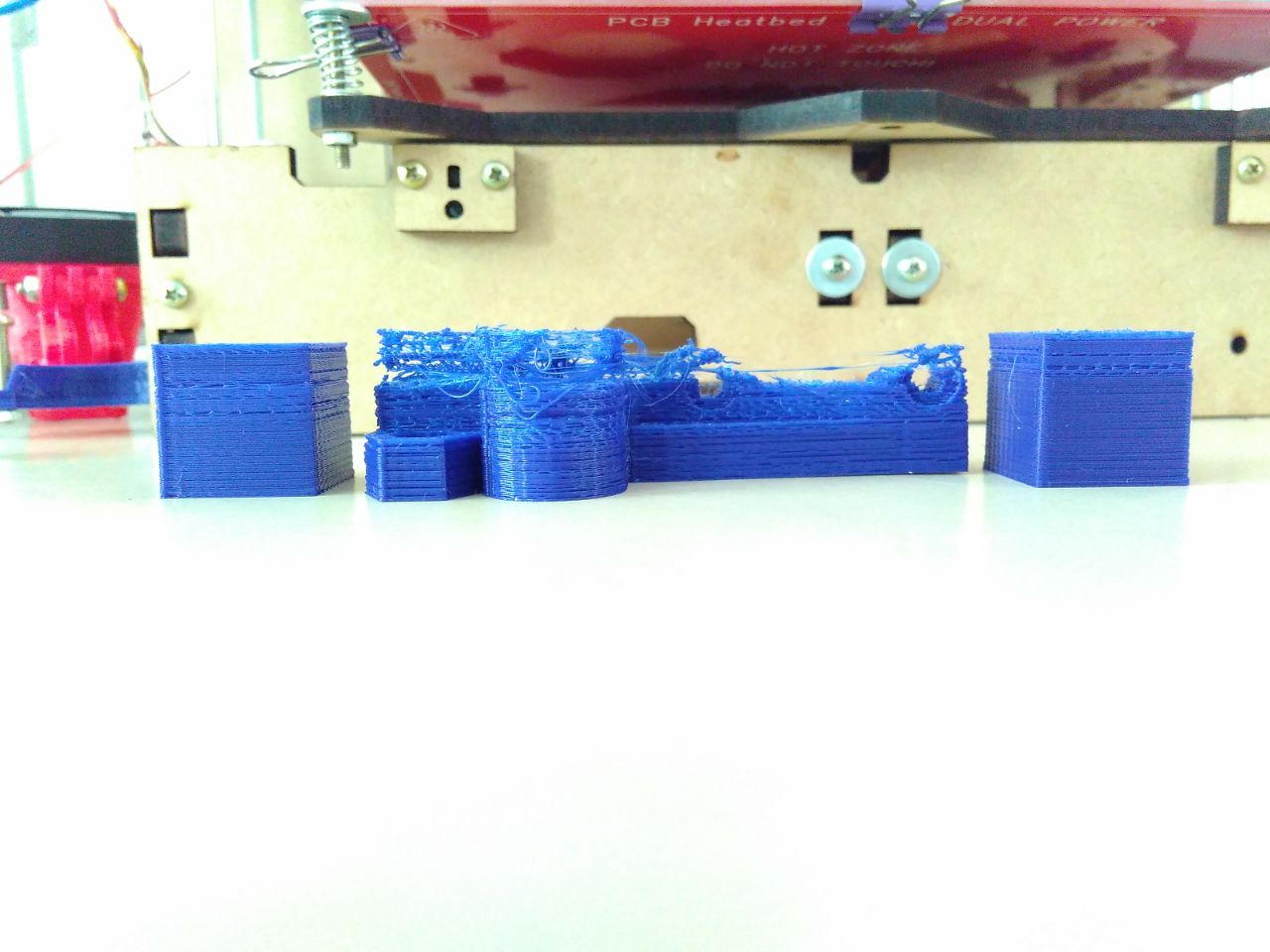

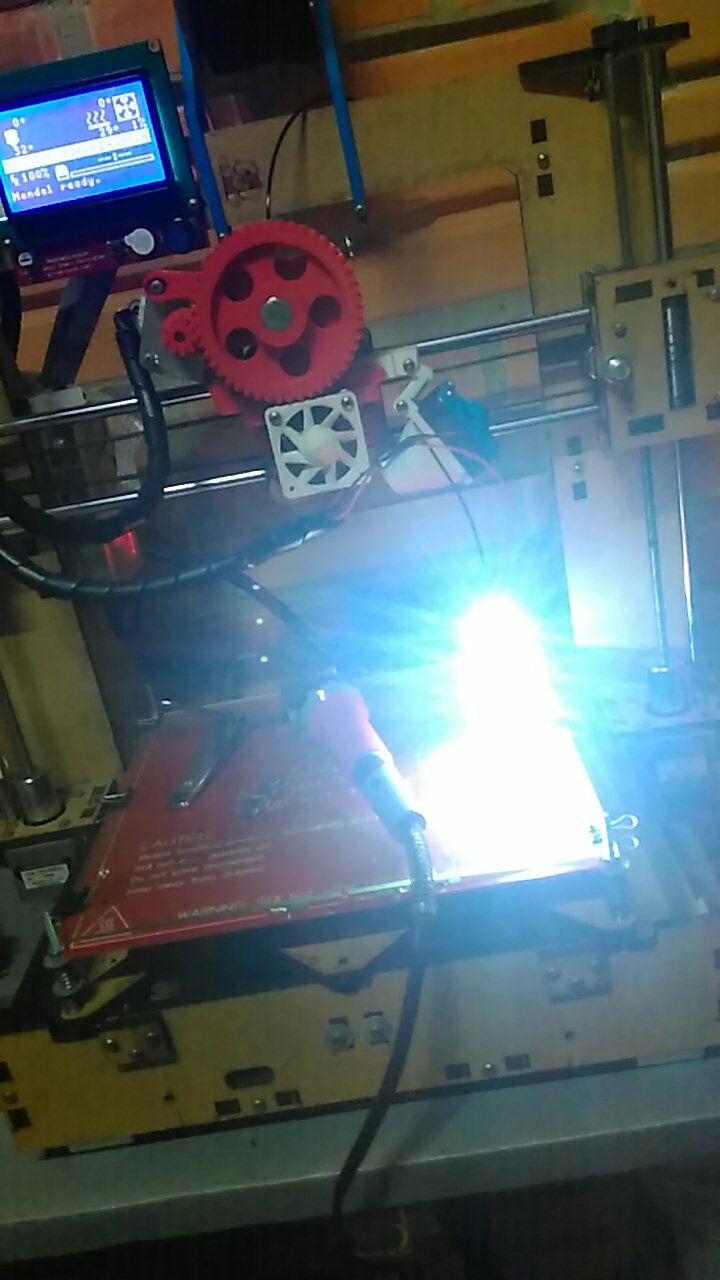

It's working !

After some time in Campinas-SP (Brazil) doing my internship on Intel, doing some cool stuffs, I am back to my city and my 3d printer .

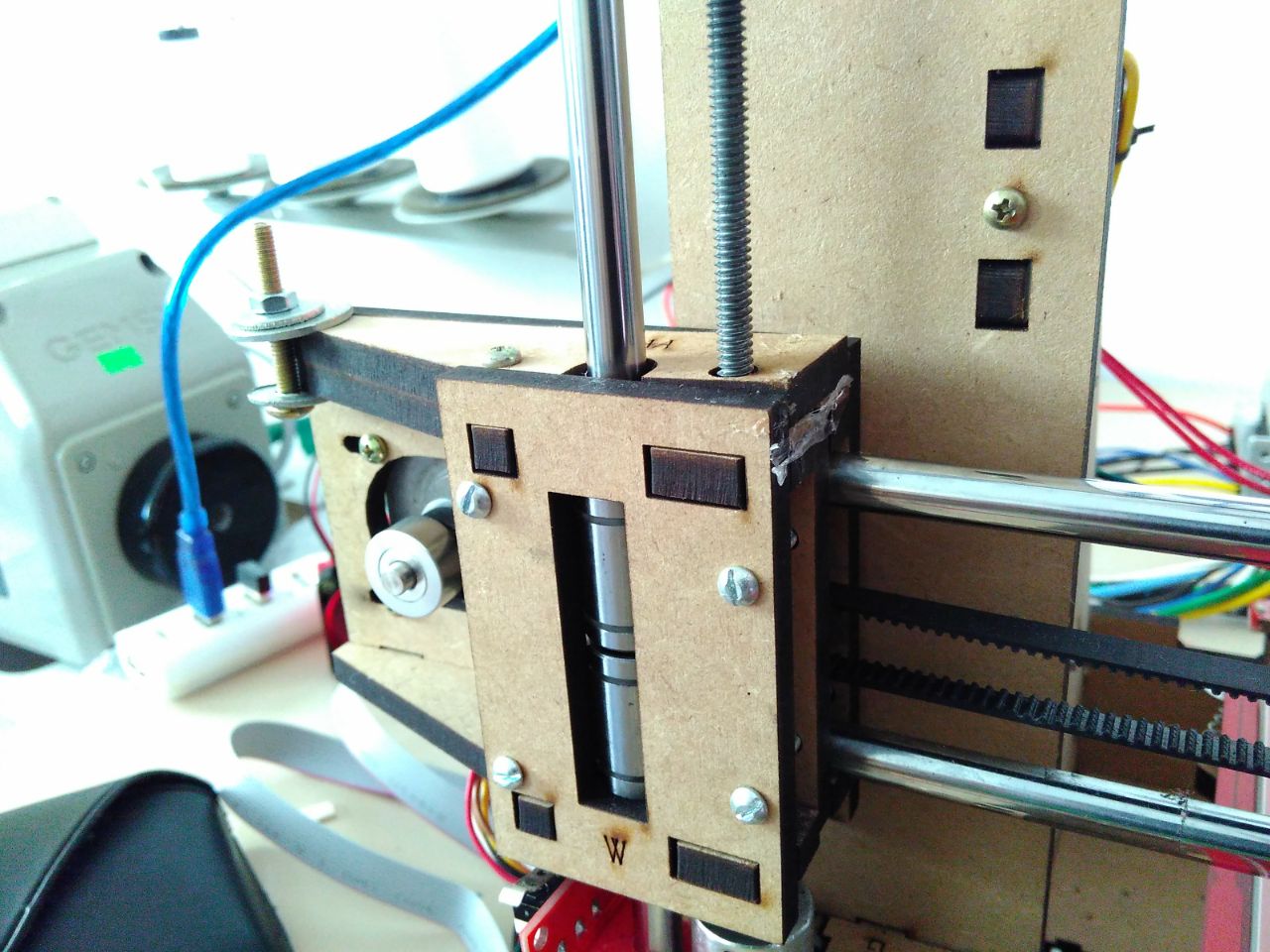

Willian (The guy with the cool blog in the top header) was working with his own 3d printer and have done a extruder to me (You can see the photos below). After one day wiring the things and some tests, the printer is alive !

To make your printer a cool IoT device, add a respberry with Arch linus, wi-fi adapter and Octoprint to print and view the progress in your browser in computer or cellphone.

Update [03/2020]

I lost a bunch of photos from my old printer in my old server, here you can check a bunch of photos that I got from some friends from my printer.